EonCoat Weldable Coating For Tank Bottoms

Prevent Corrosion Permanently

EonCoat’s two layers of protection work together to prevent corrosion at the molecular level.

Environmentally Friendly Corrosion Protection

EonCoat Corrosion Protection Coating is water-based, inorganic, and has NO VOCs, NO HAPs, no toxins, and no odor.

Industry Leading 30-year Warranty

We are confident our product will work. Therefore, we guarantee no rust on your steel for 30 years!

“The worst sale we could ever make is one that doesn’t meet the customer’s needs.”

Tony Collins

Founder and Chief Executive Officer of EonCoat, LLC

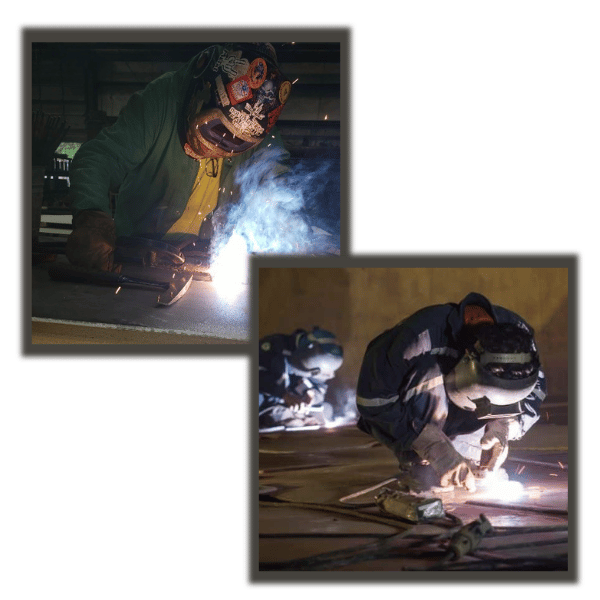

Weldable Corrosion Protection Coating for Storage Tank Bottoms and More

EonCoat Weldable Coating’s corrosion protection is essentially indistinguishable from our EonCoat Corrosion Protection Coating in terms of application. What sets EonCoat Weldable Coating apart from the others is its ability to protect carbon steel from corrosion before and after the welding process. Temperature rating up to 1202°F (650°C), EonCoat Weldable Coating enables you to weld to the backside of carbon steel without damaging the protective coating. This really is a ‘seeing is believing’ type of permanent corrosion protection.

Other Benefits and Recommendations

Learn More About Our Weldable Corrosion Prevention Technology

Science & Technology | Video Proof Showing Welding after Coating | Industries Served | SDS & Tech Sheets

Are you ready to purchase EonCoat Weldable Corrosion Protection Coating?

Where do you use EonCoat Weldable Corrosion Protection Coating?

EonCoat Weldable Corrosion Protection Coating protects your carbon steel during and after welding. After applying EonCoat to your asset, you can weld on the backside of the coated steel without damage to the steel or the EonCoat. With a heat rating of up to 1112°F (600°C), this makes it ideal for the soil-facing side of tank bottoms, steel tanks before and during assembly, and pipelines before flanges are attached, to name a few.

Storage Tanks

- Chemical Storage Tanks (Exterior)

- Oil Storage Tanks (Exterior)

- Soil-facing Side of Tank Bottoms

- Tank Steel Where Welding Will Occur

Oil & Gas Industry

- Natural Gas Pipelines

- Pipelines

- Sweating Pipelines

- Petroleum Refineries

Other Carbon Steel Assets

- Industrial Equipment That Gets Welded

- Marine and Offshore Platforms

- Mining Equipment

- Structural Beams

Are you ready to purchase EonCoat Weldable Corrosion Protection Coating?

Large or small, we coat them all!

How can you purchase EonCoat Weldable Coating?

EonCoat Weldable Coating is available for purchase in two forms. For smaller jobs, touchups, trials, and demonstrations, you can purchase prefilled 600 mL cartridges that work seamlessly with the dual-component cartridge spray gun. For larger jobs, you can purchase EonCoat Weldable Coating as a kit of 9 gallons –that’s 4.5 gallons of Part A (acid) and 4.5 gallons of Part B (base).

From a test run to full-scale coating projects, we will help you succeed.

How is EonCoat Weldable Coating applied?

You can apply EonCoat Weldable Coating by either the dual-component cartridge spray gun or the high-pressure plural pump. Both application methods are straightforward. Because many jobs involving EonCoat Weldable Corrosion Protection Coating are large application projects such as tank bottoms, the high-pressure plural pump is the most common method. However, because “seeing is believing,” many customers prefer to start with a trial application with the dual-component cartridge spray gun.

Offshore and onshore – let’s talk!

What industries benefit from using EonCoat Weldable Corrosion Protection?

We engineered EonCoat Weldable Corrosion Protection Coating to be used in various industries while focusing predominantly on the soil-facing side of tank bottoms. You can use the protective coating on any carbon steel asset that will require subsequent welding. The high-temperature rating allows this coating to be utilized in industries such as oil and gas, offshore platforms, petrochemical facilities, and petroleum refineries, to name a few.

Let’s eliminate corrosion together!

Are you ready to purchase EonCoat Weldable Corrosion Protection Coating?

Are you ready to increase the lifecycle of your tank bottom? Do you want to decrease your aboveground storage tank’s lost production opportunity while increasing safety and reliability? The team at EonCoat makes it easy to get started by clicking the Request A Quote button below. Your Corrosion Expert will be with you from the first email until job completion.

Do you need help determining if EonCoat’s Weldable Corrosion Protection Coating is the best option for your carbon steel asset?