Science and Technology of EonCoat

EonCoat’s technology is a fundamentally different approach to corrosion resistance. Traditional industrial coatings work on the principle of keeping water away from the surface by creating a water-resistant barrier. The problem is that no barrier is impermeable – and polymer barriers get weaker every day that they age. So eventually water reaches the metal and rust forms. EonCoat’s patented formula approaches protection by chemically bonding to steel and creating an alloyed layer that is inert. This means that even if water reaches the metal – nothing happens. The steel can now protect itself rather than counting on a barrier. On top of this alloyed layer, EonCoat creates a thick ceramic made of phosphates and silicates. If the alloy layer ever gets damaged this ceramic will leach a little phosphate onto the steel and fix the alloy layer. A true seal healing mechanism that will last for the life of the asset.

Phosphate Ceramic Steel Coating

EonCoat is user-friendly and highly effective. The phosphate ceramic coating is easy to apply. Simply spray EonCoat through a plural pump with a remote mix manifold. Two components, an acid, and a base, mix just before contact with carbon steel.

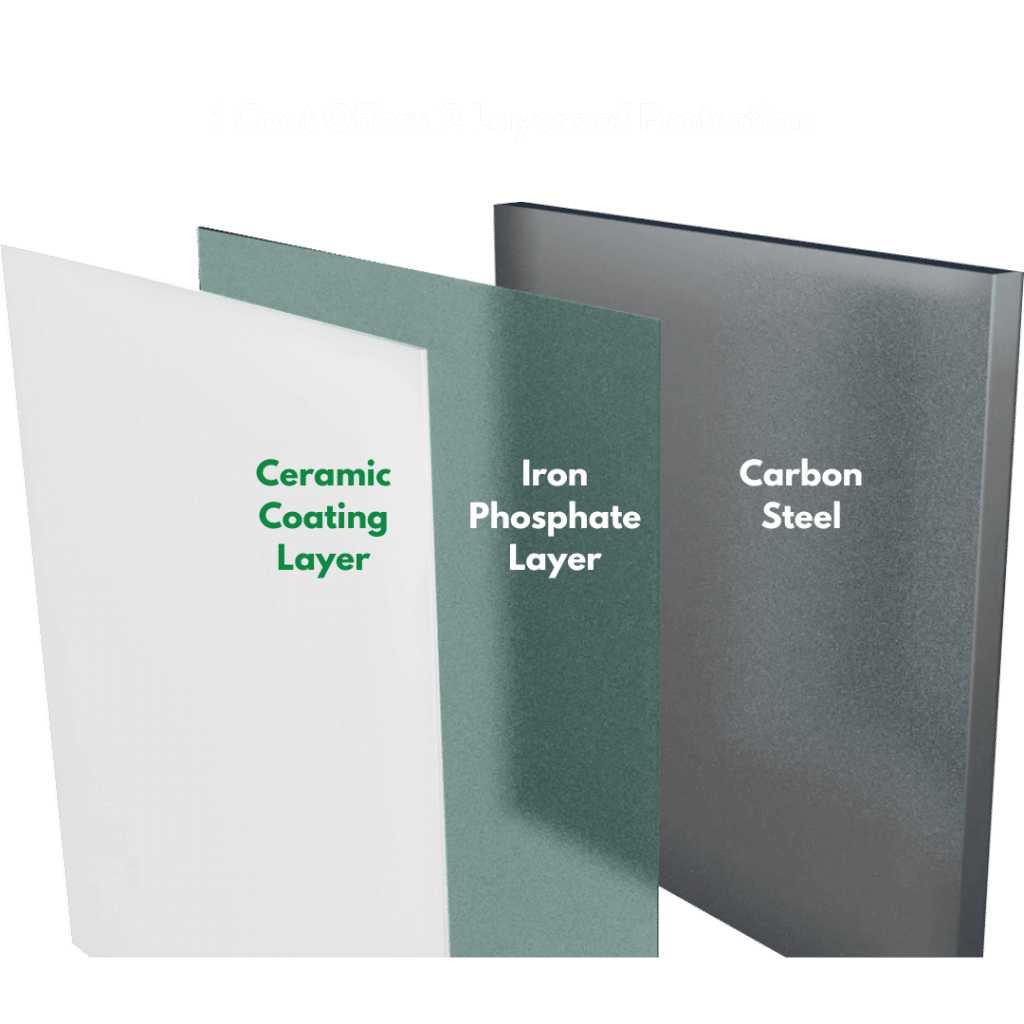

Upon contact with EonCoat, the surface of the steel forms an alloyed layer of amorphous iron magnesium phosphate. This true alloy layer, about 5 microns thick, serves as the primary defense in preventing the steel from corroding. On top of the passive alloy, a Chemically Bonded Phosphate Ceramic layer forms. This layer is 20-30 mils. This layer serves as a phosphate reservoir, allowing the steel to self-cure by maintaining the alloy that is chemically bonded to the steel.

This technology requires none of the toxic or flammable materials used by polymer coatings. There are no VOCs to contend with. NASA found it to be the most effective coating they ever tested, and they tested it when looking for an environmentally friendly product. Click here to learn more about NASA’s evaluation of EonCoat.

EonCoat: The Permanent Corrosion Solution

What makes EonCoat different?

EonCoat is the only patented, spray-applied carbon steel treatment that permanently prevents corrosion and offers a 30-year warranty. Today, most rust prevention treatments on the market lay on top of carbon steel. EonCoat has solved the rust problem, and that is why we are both different and better. EonCoat bonds to the carbon steel and chemically changes the steel surface to an amorphous magnesium iron phosphate. The white visible ceramic coating layer has a reservoir of phosphate that feeds this alloy layer over time.

Iron Phosphate Layer

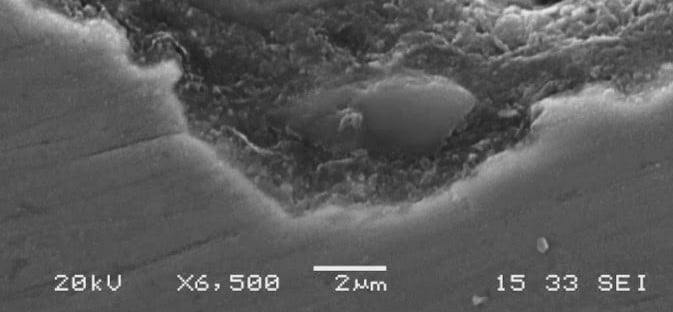

The Magnesium Iron Phosphate alloy layer is about 5 microns thick. That may not seem like a lot, but it is a thousand times thicker than the protective layer that forms on stainless steel. Electron microscopy clearly shows the chemical bond that results from the steel reacting with the patented EonCoat formula. The resulting alloy is a permanent protective layer against corrosion.

Ceramic Layer

The second layer of protection delivered by EonCoat is a 20-30 mil thick ceramic shield that serves as a phosphate reservoir to continuously re-phosphate the steel in case the alloy layer is damaged. This ceramic layer is chemically bonded to the iron phosphate alloy layer. The ceramic is very hard and provides strong abrasion resistance and high impact resistance.

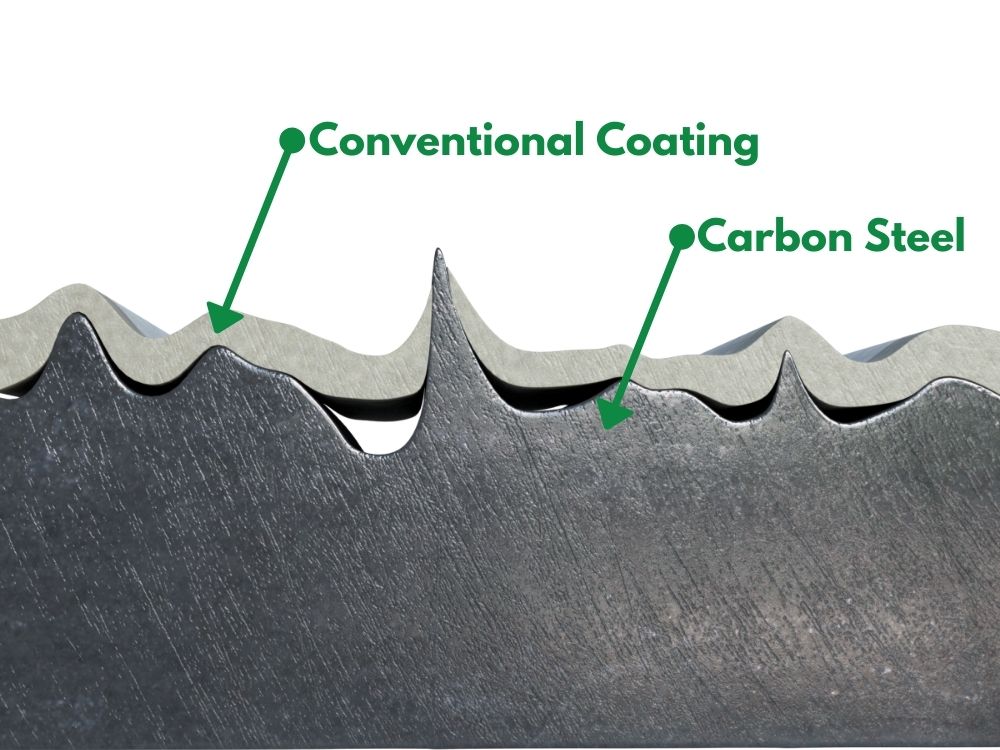

Chemical Charge Eliminates Gaps and Phosphates the Steel

Due to its chemical charge, EonCoat is actually pulled down into the valleys of the substrate profile. Unlike traditional coatings that sit atop the profile with coverage gaps in the valleys where corrosion begins, EonCoat bonds intimately (chemically) with the entire substrate. There are no gaps. An amorphous alloy layer of iron phosphate forms. This contiguous phosphate layer is created through a chemical reaction with the steel. Corrosion cannot get ‘underneath’ this stable covalent bond because the layer is actually part of the steel – not a barrier sitting on top of the steel.

Why Traditional Barrier Coatings Fail

Traditional coatings do not bond to the carbon steel surface.

Traditional barrier coatings fail because they sit like a tarp over steel. Inevitably the tarp gets torn, moisture enters, and the steel corrodes.

The Alloyed Steel Will Not Corrode

EonCoat is a self-healing alloy. First, the coating forms a magnesium-iron phosphate alloy layer with the steel. Then a ceramic topcoat forms over the alloy layer. The ceramic functions as a phosphate reservoir to continuously protect the alloy. If the ceramic is scratched or chipped, it has no effect on the corrosion protection of the alloy. The steel remains protected. And even if someone cuts a scribe line through the ceramic and through the magnesium iron phosphate alloy, the ceramic layer will leech phosphate to re-alloy the steel.

EonCoat is NOT a barrier coating.

No barrier coating can provide this self-healing ability to alloy steel.

Watch this video to see how well-protected the steel is against corrosion with the iron phosphate layer alone after coating.

Do you want to become an expert on all things EonCoat? Download our Free E-Book and Crash Course to learn how EonCoat will save you time and money while permanently protecting your carbon steel assets from corrosion. You will receive one email daily over the course of five days, making it easy to learn at your own pace.

In this Free E-Book and Crash Course, you’ll learn:

- How EonCoat works.

- How safe is EonCoat?

- What are the cost benefits of Eoncoat?

- Who is currently using EonCoat?

- How is EonCoat Applied?

Are you ready to speak with a Corrosion Expert?