How To Prepare Surface for EonCoat while Spending Less Money.

EonCoat is not a barrier coating or a paint but rather a surface treatment, similar to phosphating. To alloy the carbon steel surface, it is not necessary for all iron oxide to be removed, but it is essential for all other surface contamination to be removed (more about that later). It is important to understand the why behind these instructions.

EonCoat must physically touch the carbon steel in order to alloy it. If you spray EonCoat over a contaminated surface, the ceramic will fail and not protect your carbon steel asset. If tiny areas are missed, this will cause the ceramic to dissolve, and your asset will not be protected.

Prior To Blast Cleaning

Prior to the blast cleaning, the following things should be removed from 100% of the carbon steel:

Don’t worry about remembering everything from this Surface Prep Checklist while working onsite. Download Checklist Here.

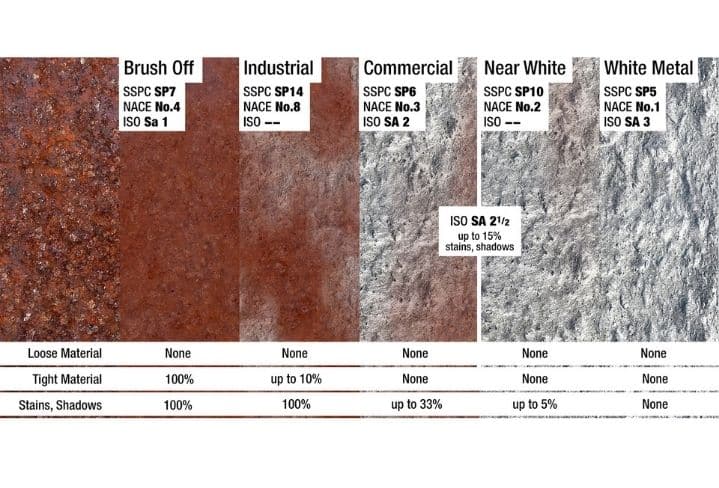

This is the NACE Standard.

EonCoat standard fits somewhere in between commercial & industrial blast

and is why we recommend commercial blast.

Preparation of Carbon Steel – Abrasive Blast Cleaning

All carbon steel surfaces to be coated with EonCoat may be abrasive blast cleaned similar to SSPC-SP 6 / NACE 3 / SA 2, commercial blast cleaning or better to an anchor profile of at least 3 mils (75 microns). The important thing to remember is that only steel or iron oxide (FeO) remain on the surface during the coating process.

Abrasive media should be equal to Medium grade BLACK BEAUTY®.

Recyclable blast media must be clean and free from dust, oil, grease, or any other detrimental matter.

Anchor profile is suggested to be measured by using Textex-Replica profile tape, or equivalent, prior to the application of EonCoat.

Once all foreign materials and mill scale are removed, you may allow the surface to degrade (flash rust).

Abrasive blast cleaning will produce a cleaning and finishing action. You can impact the finishing effect by controlling such factors as:

WARNING: Abrasive cleaning is supposed to be a scrubbing action, not a peening process! Therefore, controlling the angle of the cleaning gun is critical. A peened surface is not reactive and therefore, not suitable for applying EonCoat.

The Blast Gun, the Machine, and the Media

A blast machine is normally operated around 90 PSI at the nozzle. NACE 3 / SSPC-6 / SA 2 gives typical blast cleaning rates based on the nozzle size and pressures.

Nozzles made of tungsten carbide are the best choice. If your compressor cannot keep up with the blaster, choose a smaller nozzle for the gun. If you have plenty of pressure at the gauge, but do not seem to feel it at the gun, look for an obstruction in the abrasive pickup line or for something stuck in the nozzle.

Acceptable abrasives include coal slag (BLACK BEAUTY), aluminum oxide, garnet, silicon carbide, and steel grit.

The compressed air used for blasting should be free from water and oils. Adequate moisture/oil separators should be used to ensure the elimination of all contaminants. Cleanliness of the air can be checked by operating the line without abrasive media through a white cloth in accordance with ASTM D4285, Standard Test Method for Indicating Oil or Water in Compressed Air, which describes if any oil or water is found on the cloth, the separators should be cleaned until subsequent 20-second tests prove satisfactory.

There is no reason to blast steel to a white metal before applying EonCoat. At the time of coating, the degree of flash rust should be moderate (M) as listed in SSPC WJ standards for the maximum degree of flash rust.

For the success of your carbon steel and its new EonCoat, we have a few additional reminders:

Download our Detailed Surface Preparation & Detailed Application Guide

Are you ready to speak with a Corrosion Expert?