We have all learned to ask about a coating’s pull-off strength. But often, as technicians, we do not know why we ask. For polymer coatings, pull-off strength may be important. There are indications that a correlation exists between corrosion and pull-off strength for polymer coatings.

For Polymer Coatings

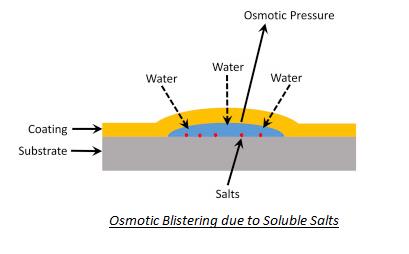

The reason is Osmotic blistering. All coatings are permeable, though some are less permeable than others. If there is any salt underneath a coating it will pull water through the polymer. Osmotic blisters are caused by an accumulation or concentration of moisture at various points within a coated film, usually through:

- Solvent or water entrapment when overcoating too soon.

- Permeation of the lining system by moisture.

- Surface contamination between coats.

- Surface contamination due to water-soluble salts.

- Thermal effects due to expansion and contraction during service. When soluble salts or solvents become trapped, moisture will penetrate the coated film to equalize the concentration of salt or solvent on either side of the film

Where significant thermal gradients are present, moisture on the warmer side will attempt to condense on the cooler side of the coated film. When the osmotic pressure overcomes the paint’s own adhesive force, a blister will form. High pull-off strength resists the formation of blisters under a polymer coating.

Does it really matter?

Although pull-off strength is an important parameter to keep in mind when selecting polymer coating systems, the recent article, “Comprehending Pull-Off Adhesion Testing” in JPCL, December 2020

By Rob Francis, R A Francis Consulting Services Pty Ltd concluded as follows-

- There are a number of commercial devices available, but results can differ significantly between them. For example, the mechanical, spring-operated device will give pull-off values about half that of pneumatic or hydraulic types.

- The relatively poor repeatability and reproducibility of the test methods make obtaining and interpreting meaningful results difficult.

- There is no convincing evidence that such results provide an indication of long-term coating performance.

- Most failures will be cohesion within the coating, which is a measure of coating tensile strength but does not relate to coating adhesion.

- Cohesive strength will normally decrease as a coating undergoes weathering and pull-off strength may be used to monitor such breakdown.

The conclusions made by Rob Francis are supported by multiple studies done by peers in the coating industry since the adhesion (pull-off) testing gained acceptance in the analysis of coating quality. The study presented by Rob Francis raises the question –Does Coating Pull-off strength matter?

Why It Is NOT Important for EonCoat?

It is important to realize that none of these issues apply to cementitious inorganic coatings, especially porous ones. Water cannot create pressure under the chemically bonded iron phosphate layer because it is not a polymer film. Water can move in and out of the ceramic with ease.

EonCoat is a ceramic coating. The corrosion protection from EonCoat comes from the alloy layer created as part of the steel. The ceramic is only there to provide extra phosphate if it is ever needed. It is just one of the things that set EonCoat apart from convention corrosion protection systems.

Ready to Learn More About EonCoat?