Barrier Coating Alternative Treats CUI

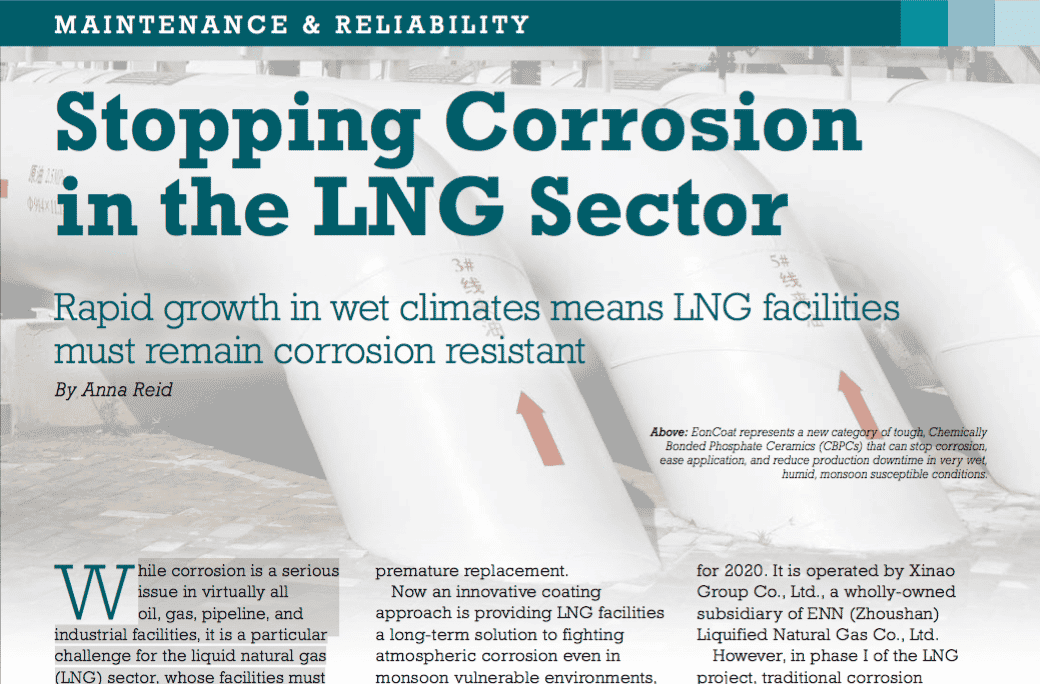

With asset usage critial and community and regulatory pressure always looming, it is essential that tank farm owners proactively prevent any loss of containment with reliable, cost-effective corrosion protection. This is crucial since atmospheric corrosion is one of the main culprits of tank leaks, containment loss, and early replacement. Read…