Intercity Passenger Rail Grant Application Information

AMENDMENT: Since EonCoat published this blog, the FRA has added additional money for this grant allocation. The new available total amount is $4.6 billion USD. When the additional money was announced, the due date for this grant was changed to 5:00 PM ET, on April 21, 2023.

For this first blog of 2023, we want to help you tackle something promptly – how to get money for your rail projects! Specifically, we are focusing on the Federal-State Partnership for Intercity Passenger Rail Notice of Funding Opportunity (NOFO) for rail outside the Northeast Corridor (NEC) and grant application standards. There is a separate NOFO for the NEC. The NEC project timeframe has different criteria and deadlines, so we’ll get to those in a separate blog.

If you’re searching, this is opportunity # FR-FSP-23-001. This NOFO opened on December 7, 2022. Applications are due March 7, 2023, at 5:00 PM EST, for this $2.2+ billion in federal funding. Many related documents can also be found on the federal register.

Let me state very clearly and up front that everything I’m referencing in this blog comes predominantly from two different sources. The first source is the previously linked Federal Partnership for Intercity Passenger Rail NOFO from the Federal Railroad Administration’s introductory page. The other primary source is the EonCoat website.

Citing those references in the introduction will keep this blog from looking like your neighbor’s leftover holiday lights – the multi-color, blinking, chasing ones. I will clearly hyperlink any other references in this article.

Next week, there will be a second follow-up blog so make sure you come back for Part II. In that blog, we’ll share what our other rail industry customers and rail-specific research have to say about EonCoat.

How Does EonCoat Fit into the Grant Selection Criteria?

That’s the question we want to answer for you with this blog. Let’s look at some of the key concepts from the document. The NOFO cogently states, “Discretionary grant awards, funded through the FSP Program, will support projects that improve safety, economic strength and global competitiveness, equity, climate and sustainability, and transformation consistent with the U.S. Department of Transportation’s (DOT) strategic goals.”

That’s a lot, so let’s break it down into those smaller categories.

Improve Safety

Using EonCoat on fasteners, plates, and rails extends the lifecycle of those parts by as much as 300%. This means you can decrease stopping or rerouting trains for repair or replacement work. Additionally, this reduces the number of rail employees on the tracks for annual replacement work. The pieces protected by EonCoat may only need replacement every two to three years. That’s fewer people on the tracks and fewer rail employees in a potentially dangerous situation.

Economic Strength, Global Competitiveness, and Support of Domestic Manufacturing

EonCoat’s headquarters and secure manufacturing facility are located in Fuquay-Varina, North Carolina, United States. This makes us a small-town company with global customers who demand permanent corrosion protection. While we have a network of Authorized Distributors on other continents, EonCoat, LLC staff personally handle all domestic sales.

Equity and Environmental Justice

You’ll need to use the Transportation Disadvantaged Census Tract (Historically Disadvantaged Communities) to determine if your unique proposal falls inside of this selection criteria.

The NOFO discusses Environmental Justice concerning the development, implementation, and enforcement of environmental laws, regulations, and policies. Because EonCoat is safe and has permanent corrosion protection, all three EonCoat products fall well inside this definition.

EonCoat has publicly conveyed that every community and its workers have the right to be protected from environmental pollution. Everyone has the right to live, work, and play in a safe and clean environment. In that same blog article, we call the leaders of all other protective coatings to follow us to a safer environment.

To quote Tony Collins, our CEO, “VOCs and HAPs are the next big tobacco class action suits. We’ve known for years they are dangerous, but other manufacturers continue to expose workers and their communities to the dangers.”

Climate and Sustainability, Reduce Pollution and Support Fiscally Responsible Land Use

We engineered EonCoat specifically for applicator and environmental safety. EonCoat makes it easy to review the TDS and SDS for each of our products. EonCoat is:

- inorganic,

- water-based, and

- non-flammable.

Additionally, EonCoat has no:

- VOCs,

- HAPs,

- TOXINs,

- ODOR, and

- requirement for excessive PPE (only safety goggles and an N95 are required).

By eliminating the use of any solvents, we have eliminated HAPs in our products. It’s the HAPs that contribute to the creation of visible smog. Therefore, selecting EonCoat can be directly tied to lowering smog.

VOCs (volatile organic compounds) are carbon-based materials that evaporate into the air. As they evaporate, most of the VOCs pollute the air. As a result of our commitment to applicator and environmental safety, EonCoat has eliminated VOCs from all our products.

EonCoat accomplishes these bold claims, in part, by utilizing dual-component application methods. By using this readily available technology, EonCoat realizes its goal of eliminating many of the deaths and long-term debilitating illnesses employees suffer because of VOCs, HAPs, and toxins. You won’t find EonCoat’s name in the list of companies being sued by various states because of preventable worker illness, death, or making false claims about safety.

According to the NOFO, this grant focuses on several environmental standards. The funding “includes all related Federal laws and regulations including the Clean Air Act, Section 4(f) of the Department of Transportation, Section 7 of the Endangered Species Act, and Section 106 of the National Historic Preservation Act.

With that, consider these quotes sourced directly from our report that clearly states EonCoat has no VOCs or HAPs:

- When discarded or spilled, this product is neither a hazardous waste as defined in current federal regulations 40 CFR, Part 251 (RCRA) nor toxic pollutant as currently defined by the Federal EPA per section 307 of the Clean Water Act.

- This product does not contain substances considered by OSHA, NTP, IARC, or ACGIH to be “probable” or “suspected” human carcinogens.

- Waste from this product is not hazardous as defined under the Resource Conservation and Recovery Act (RCRA) 40 CFR 251.

- No ingredients in this product are subject to SARA 313 (40 CFR 372.65C) notification.

EonCoat is safe for the environment where you work, live, play, and ride the rails.

Infrastructure Resilience to all Hazards, Including Climate Change

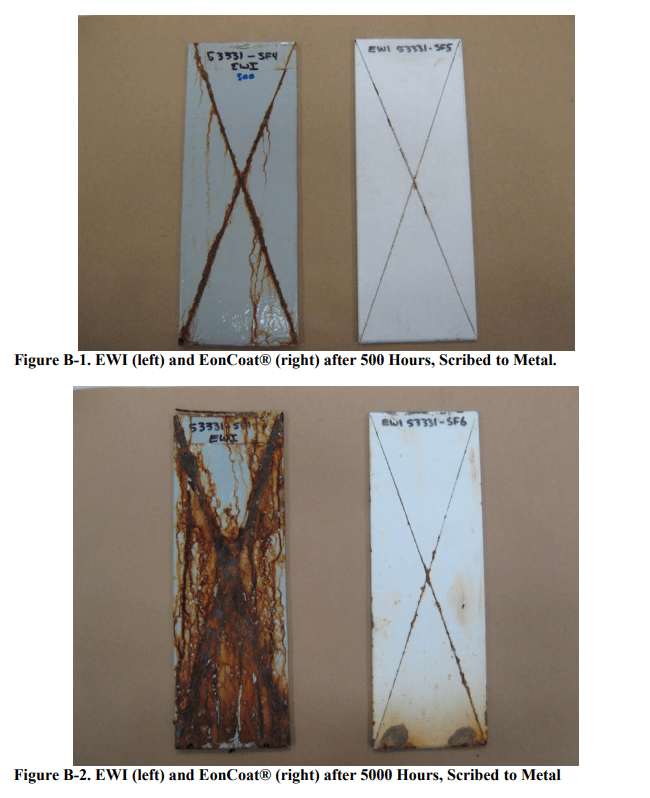

As a nation, we must acknowledge that the rail industry is a piece of our critical infrastructure and must be resilient. Every product from every company must contribute to our nation’s infrastructure resilience. EonCoat has been leading the way with rigorous, third-party testing, in addition to longitudinal and large in-house testing. EonCoat has extensive third-party testing to demonstrate how well all three products perform in some of the most corrosive environments.

Is your rail infrastructure in a muggy, buggy, salty, smelly, or chilly environment? EonCoat has a test for that!

The Grant Writing Vocabulary Lesson

Many professionals will be sitting at the table as you write these grants. Some things can get lost in translation between materials engineers, accountants, and grant writers (just to name a few of our favorite people). To help with the language, we are including some key terms and their definitions below.

Capital Project: Project for acquiring, constructing, improving, or inspecting rail equipment, track, and track structures. This includes pre-construction activities such as design and engineering.

Commuter Rail Passenger Transportation: Short-haul rail passenger transportation in metropolitan and suburban areas usually having reduced fares, multiple rides, commuter tickets, and morning and evening peak period operations.

Cost-Benefit Analysis: Data-driven and transparent analysis using a ‘no-build baseline.’ This one is so important that it gets a separate hyperlink – click here to see the Guidance for Discretionary Grant Programs.

Environmental Justice: This is defined by the EPA as “fair treatment and meaningful involvement of all people regardless of race, color, national origin, or income, with respect to the development, implementation, and enforcement of environmental laws, regulations, and policies.”

FRA: Federal Railroad Administration

Intercity Rail Passenger Transportation: Rail passenger transportation, except commuter rail passenger transportation.

Improvement: Repair or enhancement to existing rail infrastructure, equipment, or facility, or construction of new rail infrastructure, equipment, or facilities, that results in efficiency of the rail system and safety of those affected by the system.

NOFO: Notice of Funding Opportunity

Outside the NEC: Outside the Northeast Corridor. This is the exclusionary boundary of this funding opportunity. The Washington, DC, to Boston, MA, route (and a few associated routes) is excluded from this funding opportunity.

State of good repair: A condition in which physical assets, both individually and as a system, are:

A. Performing at a level at least equal to that called for in their as-built or as-modified design specification during any period when the life cycle cost of maintaining the assets is lower than the cost of replacing them.

B. Sustained through regular maintenance and replacement programs.

TRACKS:

Track 1 Project Planning

Track 2 Project Development

Track 3 FD (final design) and Construction

EonCoat Exceeds Standards

EonCoat desires this blog about intercity passenger rail service to be a great jumping-off point as you write your grant proposal. Above all, we hope your most significant takeaway point is that EonCoat meets or exceeds the standards stated in the NOFO. Specifically:

- EonCoat is proven to eliminate the annual replacement programs by extending the lifecycle of plates, fasteners, and rail pieces.

- By extending the lifecycle of these essential rail parts, rail companies can use those previously allocated dollars for other mission-critical projects. This makes EonCoat the fiscally sound decision for corrosion protection.

- EonCoat’s permanent corrosion protection is ideal in so many conditions. However, when viewed through the lens of this funding opportunity, all three EonCoat products meet or exceed the stated requirements.

If your team is ready to start a conversation with a Corrosion Expert, click the Contact Us button below. Your Corrosion Expert will reach out to you within one business day. They will be able to answer in-depth questions about the EonCoat products and start discussing your application project.

We’ll see you back for Part II next week!

Ready to Learn More About EonCoat?