Watch the video below or continue to the transcript below

Video Transcript

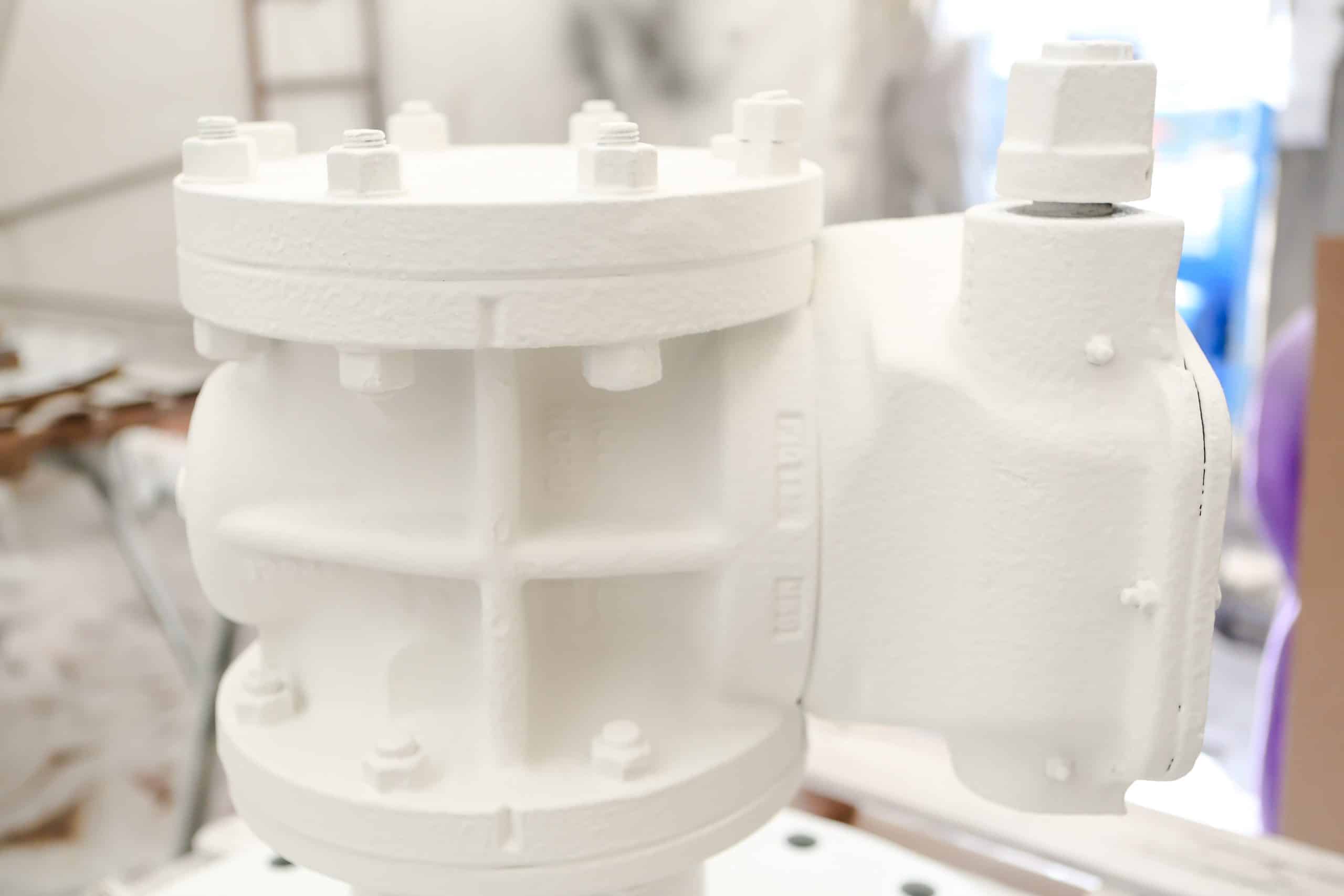

A Corrosion-Resistant Coating

EonCoat is a new material science and a completely different way to protect steel against corrosion. We call it a corrosion-resistant coating, but the truth is, because it alloys the top layer of steel, it’s not just what you can see with your own eyes that protects the steel.

Putting EonCoat to the Test

In just a few minutes, you’ll see something remarkable: a coating that is protecting the steel — even when it’s been scraped off.

One-third of the plate is bare metal, as you can see here. The other two-thirds of the plate were coated with EonCoat corrosion-resistant coating. But you’ll note that only the center of the plate has the ceramic coating still on it.

That’s because about 15 minutes after we coated the plate, we removed the ceramic coating from part of the plate. The purpose of this is to show you how EonCoat has alloyed the top layer of the steel.

We’ll explain the significance of this after the test.

The Rusting Results

Liberally apply with a solution of 50% vinegar and 50% water. That’s a highly corrosive mix and will rust carbon steel in a matter of minutes. You need to wait 3-5 minutes and you’ll start to see the rust form.

You will, of course, expect that the bare metal will rust. You would also expect that the part that has a corrosion-resistant coating on it not rust, and you are correct, it does not.

But, normally, when a coating is compromised, cracked, peeled, bubbles up, we call that a failure, because that means the steel can and will rust. But here, you can see that even with the coating removed, the part that was coated with EonCoat does not rust.

We have done a lot of testing like this. If you want to see more go to the NASA page to see how Nasa tested EonCoat, also check out the seawater test page to read about this interesting test we did.

Why?

Because once EonCoat comes into contact with bare steel, it chemically bonds with the steel. It actually alloys the very top microns of the steel to form a passive alloyed layer that will not corrode.

Once that happens, the ceramic coating that you can actually see is the second form of protection, because the alloyed layer that you can’t see is the first layer of protection. So if that second form of protection cracks or is compromised, it doesn’t matter. The steel beneath is still protected.

Let EonCoat Solve Your Corrosion

EonCoat is a new material science and a completely different way to protect steel against corrosion.

Ready to Learn More About EonCoat?