30 years ago, I was on-site when an industrial accident badly damaged a mill and took three lives. What I remember most is leaving the plant. The news had broadcasted that there was a significant accident at the plant. Many families had gathered outside the gate, wanting to find out if their loved ones were safe. The ambulances coming and going indicated that some were not. After recovering the bodies, I walked to my car parked outside the main gate. The faces of those people are etched in my mind forever. Desperate. Afraid. They wanted information about their loved ones. I could not tell them anything and felt ashamed that I had not prevented it.

As a visitor and not part of the plant management structure, no one blamed me. But I blame myself. It comes to mind often. I had enough knowledge about the process to foresee what might happen. But, as a guest, it was not my place to tell the customer how to operate their business. If I had spoken up, the accident likely would have been postponed and may have been prevented altogether.

This is me speaking up now. For those in management, I’m telling you something that I should have said to the managers at the mill. If you don’t fix it now, you have a problem – and it will cost you – lives and more money than you can imagine.

We expose our employees, especially painters, to a high volume of toxic fumes from VOCs. This workplace exposure will be the next asbestos/silicosis/tobacco/Hexavalent Chromium disaster. And we need to get on the right side of this issue before we wind up in a tort lawsuit so damaging that we become the next Johns Manville.

The Nasty Little Thing about VOCs

VOCs, or Volatile Organic Compounds, are nasty little things. It is the tiny size that enables them to be so deadly. Ultrafine Particles with a diameter of fewer than 0.1 μm display high velocity and penetrate capillaries and the brain. Chronic exposure to them leads to inflammation and causes cell damage. Particles less than 0.1 μm in diameter reach the brain directly through the olfactory bulb to the cortical and subcortical centers of the frontal lobe and cause damage. Inevitably, a vicious cycle of inflammation, capillary damage, and further inflammation develop, and an increase in pro-inflammatory cytokines is observed. This cycle promotes the death of nerve cells, a fundamental unit of our brains and nervous system. In simpler words – VOCs damage brains. IQ drops. Short-term exposure to certain VOCs may produce headaches and worsen asthma symptoms and respiratory issues. Long-term exposure to VOCs will cause liver or kidney damage and even cancer.

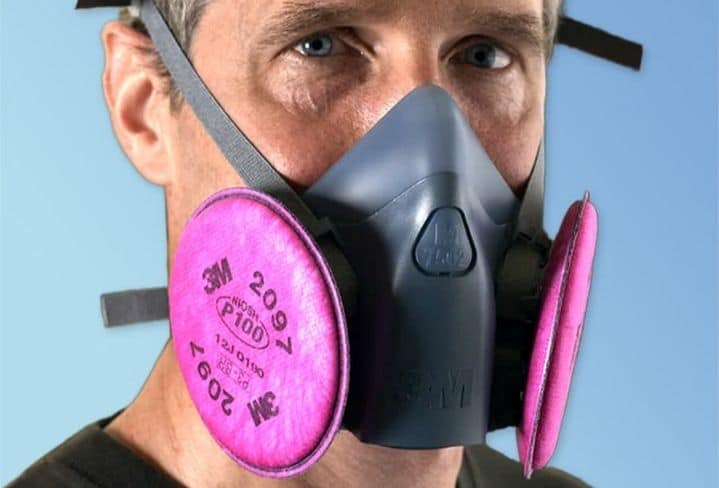

We give painters particulate masks rated as P100. That is the best we have to offer. These masks stop 99% of particles larger than .3 microns. Some of them will filter down to 50 nanometers. Guess what – VOCs are in the Pico size range – 1000 times smaller than the nanometer filtration size. Isn’t this like giving soldiers and police officers leather vests and telling them not to worry – the leather will stop bullets? The guys in the crew may not understand the difference between Pico, Nano, and Micro – but management should and must.

It used to be a joke that painters were “goofy.” It seemed that the industry attracted a weird type of individual. So when we first heard the term “painter’s dementia,” it seemed an accurate description instead of a medical diagnosis. However, by the time data was published that long-term exposure to VOCs drops IQ between 10 and 15 points, it ceased to be funny. And it isn’t going to be funny to juries when they hear about the cases of dementia this exposure has caused.

Need some anecdotal evidence about the fact that VOCs penetrate the PPE we give painters?

Kiss Your Wife With EonCoat

Some years ago, we applied EonCoat on our first tank roof. The painter came up to me the next day and said, “you got me in trouble.” “How so?” was my response. He told this story – When I got home yesterday and kissed my wife, she asked what I did today. I told her we painted the roof of tank 400. She accused me of lying and even questioned whether I might have skipped work and gone to the casino in Biloxi. Surprised by the accusation, I told her that – “no honey, we painted the roof of tank 400, what makes you think otherwise?” Her response has stuck with me – she said, “we’ve been married 15 years, when you come home you kiss me, on days when you have sprayed paint, I taste it. There is no taste today”.

This story happened eight years ago, and there have been many similar stories since. This story, though simple, has sustained me through some tough times and caused me to push forward through all the struggles of building a new business. Investing my time and money in this technology to eliminate the workplace hazards that cause so much pain has a very personal payoff. I can never atone for what happened at the mill all those years ago – but I know this technology will save many lives and improve so many more. It is my contribution, and it assuages my guilt just a little.

Ready to Learn More About EonCoat?