Seawater Corrosion Test Results

Why a Seawater Corrosion Test?

In the early days of research into EonCoat, we wanted to know if we really had something. We decided to conduct an experiment by spraying real seawater onto a coated panel alternated with high-intensity sunlight (using a sun lamp). We decided to compare what we had developed to other coatings in the marketplace. We asked friends and potential customers what coatings they thought were the best. We bought each of the coatings recommended by the folks we spoke with and coated sample panels. The friends we asked for coating recommendations wanted to be kept apprised of the results so they could see if the coating they used did best. So, we set up a webcam to enable them to view the test live along with us. And then we decided what the heck – put it live on the web and let everyone watch in real time. The experiment directly compared EonCoat to what customers thought was the best coating.

How was the test conducted?

We applied the recommended coatings along with EonCoat to 17 different test plates. All the coating systems are listed below.

- EonCoat – #14

- Carboncoat DTM 8215- #15

- Pitt-Tech DTM Industrial Enamel 90-374 PPG- #16

- Carboline Carbozinc Primer + Carbocrylic Topcoat 335- #17

- AFM Safecoat Primer + AFM Safecoat Top Coat – #18

- Pitt Guard Rapid Coat DTR 95-245 95-249 PPG – #19

- Pitt Tech Plus DTM 90-1210 PPG – #20

- Sherwin Williams PRO Industrial Primer – #21

- Sherwin Williams PRO Industrial Primer + Topcoat Pro Industrial – #22

- Sherwin Williams Zinc Clad 143-0255 – #23

- Sherwin Williams Kem Kromix Primer + Sherwin Williams Rust Preventative Paint – #24

- Sherwin Williams Kem Kromik Primer – #25

- Rustoleum Pro High-Performance Primer V-7580 – #26

- Rustoleum Pro High Performace Primer V-7580 + Topcoat Rustoleum V-7592 – #27

- Rustoleum Industrial Choice 5200 DTM Acrylic – #28

- Carboline Carbocrylic 3359 – #29

- AFM Safe-Coat Primer- #30

We put a deep scribe into each of the panels & laid them flat. Real seawater brought directly from the Atlantic was sprayed for 10 minutes out of every 4 hours. Sunlight was simulated by sun lamps (426-nano-meter light waves) in continuous 4-hour intervals for 170 days. The entire 170 days were live on the internet for all to follow. We didn’t know beforehand how we would do.

EonCoat has learned a great deal since this long-ago test of our first version of the coating (we are on version 5 now) but even then, the first version of this material science outperformed the most well-known products. We thought it would be fun for all to look back at where it all started. For more details on the experiment click here.

After 170 long days, EonCoat was the only one standing without any corrosion.

Top Performers other than EonCoat.

Two of the other coatings stood out when it came to corrosion protection. AFM Safecoat Primer + AFM Safecoat Top Coat & Rustoleum Pro High-Performance Primer V-7580 + Topcoat Rustoleum V-7592 were showing promising results until the last week of testing. At that point, they failed.

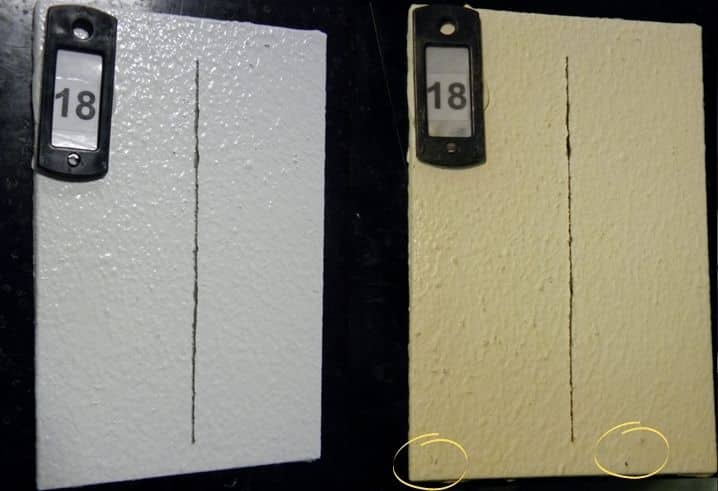

AFM Safecoat Primer + AFM Safecoat Top Coat

Day 1 (Left) vs. Day 170 (Right) – Circles Show Corrosion Pitting

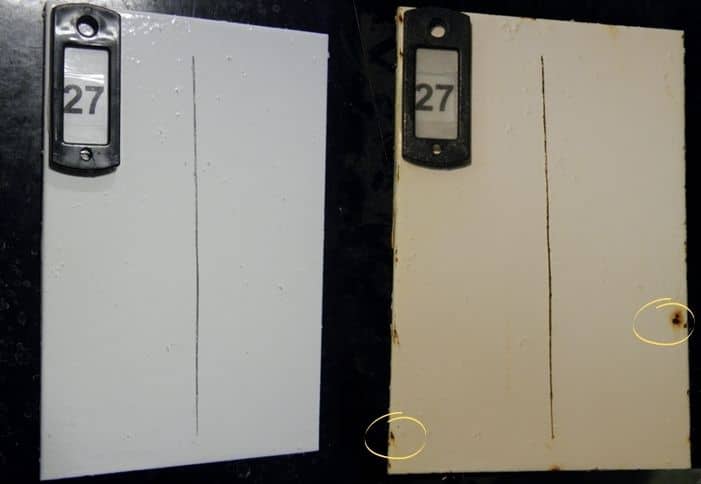

Rustoleum Pro High Performace Primer V-7580 + Topcoat Rustoleum V-7592

Day 1 (Left) vs. Day 170 (Right) – Circles Show Corrosion Pitting

Everyone else didn’t come close

Every other coated test panel failed terribly. Corrosion beat them all. Some of the coatings bubbled others just rusted right through. Here are some of them. For all the results, click here.

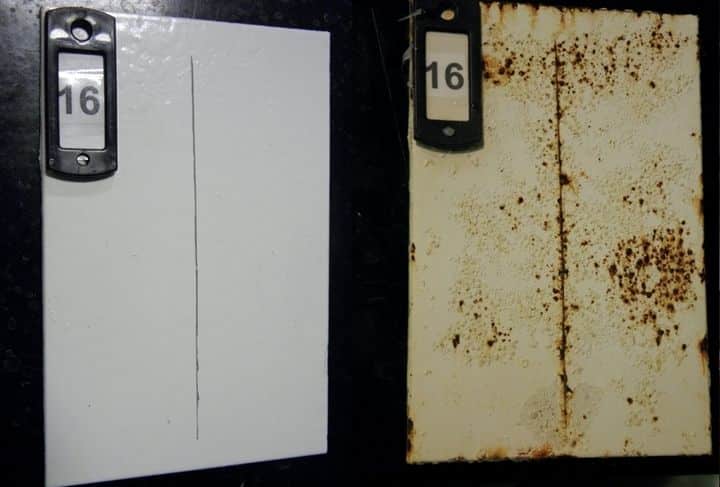

PPG Pitt-Tech DTM Industrial Enamel 90-374

Day 1 (Left) vs. Day 170 (Right)

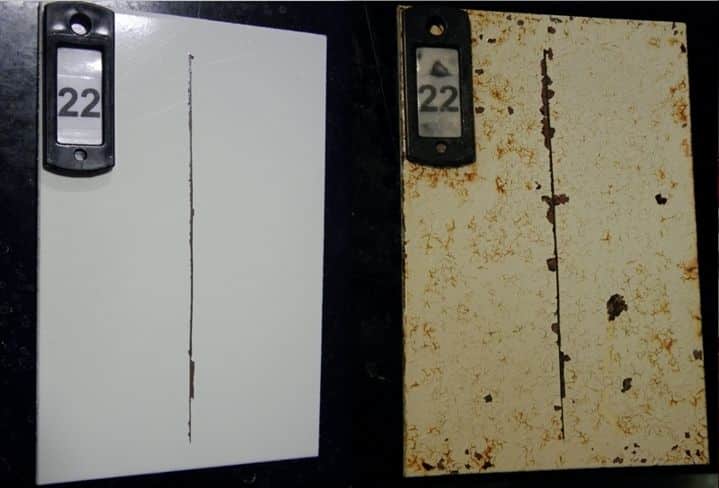

Sherwin Williams PRO Industrial Primer + Topcoat Pro Industrial

Day 1 (Left) vs. Day 170 (Right)

The results speak for themselves.

It’s pretty clear which coating is the best. To see the results of all the other coatings, watch the following video or click here. To learn more about EonCoat, download the EonCoat E-Book or Contact Us.

Do you want to become an expert on all things EonCoat? Download our Free E-Book and Crash Course to learn how EonCoat will save you time and money while permanently protecting your carbon steel assets from corrosion. You will receive one email daily over the course of five days, making it easy to learn at your own pace.

In this Free E-Book and Crash Course, you’ll learn:

- How EonCoat works.

- How safe is EonCoat?

- What are the cost benefits of Eoncoat?

- Who is currently using EonCoat?

- How is EonCoat Applied?

Are you ready to speak with a Corrosion Expert?