Prevention, Mitigation, and Detection of Pipeline Corrosion

Without stating it directly, we all expect and need pipelines to continue to do their job invisibly – without interruption or injury to the environment and people. Prevention, mitigation, and detection of all types of corrosion must all be utilized to form a cohesive pipeline safety plan.

As part of the midstream infrastructure, our collective global dependency on pipelines has come into clarity in the recent past. Consider that 99.999997% of the gas and crude oil we need to supply our energy is moved safely through pipelines in the United States. Pipelines provide the safest and least expensive way to move oil and gas.

The most severe threat to the safety of this method of transporting energy is corrosion. We must minimize and manage corrosion to ensure safety of the public and no loss of the goods. Last week we talked about preventing corrosion on pipeline externals. This week we’re going to explore prevention, detection, and mitigation of a pipeline’s internal corrosion. We think of pipeline corrosion as external because of the environments that pipe pass through, and there is plenty of truth in that. But just because the inside of the pipe is hydrocarbons doesn’t mean that they do not contain corrosion promoting impurities.

Pipelines Part 2 – Protecting the Inside of the Pipelines

There are two added layers of complexity when it comes to preventing corrosion on pipeline internals. First, it’s even harder to assess for corrosion on the pipeline internals than the pipeline external surface. Additionally, any protective coating applied to the pipe internals must take into account the substance that is being transported and how to protect the pipeline from its product.

Assessing the Internals of a Pipeline

Pipeline operators measure the wall thickness to assess the health of a pipeline. To maintain optimum wall thickness, the first layer of corrosion defense is accomplished, “normally by applying a tight control on the process parameters (e.g. water dew point in gas transmission systems, injection of corrosion inhibitor).”

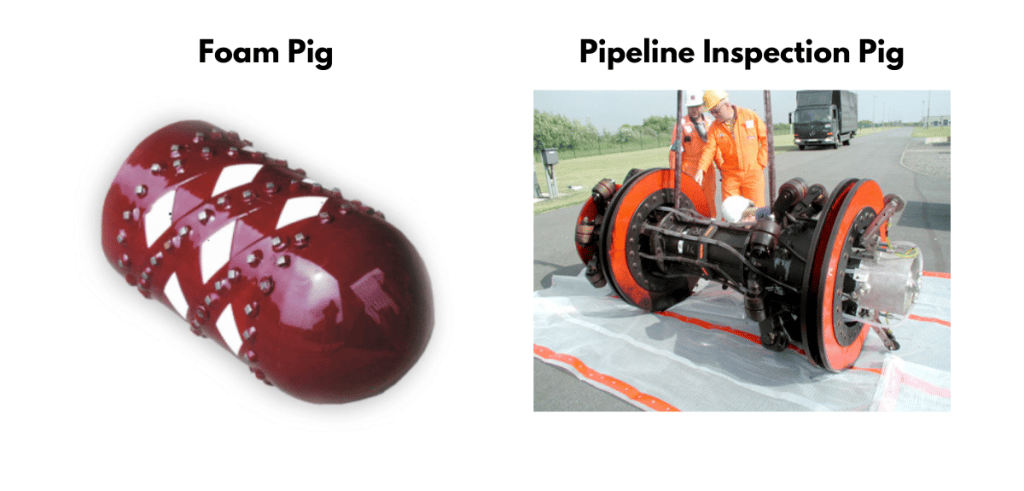

However, no amount of ‘tight control’ can completely abate corrosion. Therefore, pipeline managers can use a pipeline pig. The PIG accomplishes things like, “drying, cleaning, batching, product removal, and liquid displacement”.

Depending on the type of PIG, pigging can help you determine that corrosion has begun and where it is in the pipeline – but it doesn’t prevent corrosion. That’s because even pigging a line can leave water or other debris in a line. As we all know, water + carbon steel can be the open door to corrosion.

Image extracted from (Rigzone)

Another method of assessing conditions in the pipe is a drip-pot assembly which allows pipeline stakeholders to measure:

- Amount of liquid in the system

- Identification of the liquids

- Presence of CO2, H2S, water, and acids

- Microbial activity (via bioscreen option)

- Corrosion rate (via weight loss coupon)

- Presence of iron that indicates interior corrosion or erosion

Image extracted from (Sentry-Equip)

Both a pipeline pig and drip pot assembly can be appropriate, after-the-fact, corrosion identifiers for such things as microbiologically influenced corrosion (MIC) and hydrogen sulfide. Even better than identifying the corrosion is preventing it from ever occurring. Prevention, before corrosion even starts, is where EonCoat becomes the answer.

How Does EonCoat Provide Internal Pipeline Corrosion Protection?

With only one application required, EonCoat’s spray-applied technology lays down two layers of patented corrosion protection. A layer of iron phosphate becomes part (an alloy) of the carbon steel. Then a ceramic coating reinforces the iron phosphate by resupplying phosphate when needed and enabling the coating to neutralize small amounts of acid in the product stream.

How Is EonCoat Applied Inside a Pipeline?

EonCoat can be applied to pipelines that have a diameter greater than 12 inches. The current size limitation comes from needing to get the application equipment inside the pipe. While we are working on new technology to be able to protect smaller diameter pipelines, those products are not yet market-ready. Stay tuned to our social media and blog for details when we deploy that technology!

EonCoat applied to the pipeline internals is safe for the environment and the applicator because EonCoat:

- has NO VOC’s,

- has NO HAP’s,

- has NO Toxins,

- has NO Odor, and

- requires no solvents for cleaning up after the job.

Chemical Resistance Is King

Selecting the correct protective coating for the internals of a pipeline is the first step in ensuring that your mission-critical asset has a long lifecycle. Maximizing the lifecycle of your carbon steel pipe is one step in saving money. The less pipeline you must replace because of corrosion, the higher the ROI for your stakeholders.

One of the top 10 questions we receive is, ‘with what chemicals does EonCoat work well?’ A partial Chemical Resistance List for EonCoat products is as follows:

- Xylene

- Phenol

- Methanol

- Isopropyl Alcohol

- 25% Salt Solution

- 37.5% Salt Solution

- Vegetable Oil

- Jet Fuel

- Diesel Gasoline

- Crude Oil

This is a highly abbreviated list, and we consistently test new chemicals against EonCoat, so the list will continue to grow. Therefore, if you don’t see a particular chemical here, please contact us and ask about your unique pipeline needs.

When to Use a Topcoat

There are times when our Science Team will recommend a topcoat be applied to EonCoat. When recommending a topcoat, we consider things like pH levels, temperatures, and flow rates.

Based on the information, we might recommend durable topcoats like Epoxy Novalac, or our own EonSpartic PolyAspartic Topcoat, for chemicals which increase the desired solubility of the EonCoat ceramic layer. Talk with us about the possible need for a topcoat in your pipeline.

How To Get Started

If you have questions about protecting your pipeline, its contents, and its surrounding environment, click the Contact Us button below. You can tell us about your specific internal pipe corrosion needs. Someone will reach out to you within one business day to start identifying how we can help you permanently tackle corrosion.

If you want to continue learning more about EonCoat, sign up for the EonCoat Free E-Book. Your email is always safe with us, and you’ll receive one email per day for five days. The Free E-Book will put you well on your way to being a corrosion prevention expert!

Ready to Learn More About EonCoat?