AMPP has endorsed newly proposed legislation entitled “Bridge Corrosion Prevention and Repair Act.” AMPP has endorsed this cohesive proposed legislation because it aims to prevent corrosion and give our bridges an extended service life. Sam Scaturro, chair of the AMPP Board of Directors, states, “H.R. 8033 is a decisive step toward ensuring that our bridges are protected from the harmful effects of corrosion.”

H.R. 8033 would require all federally funded bridge projects to utilize appropriate corrosion prevention. The proposed law calls for “utilizing industry-recognized standards and corrosion mitigation and prevention methods to address:

- Surface PreparationProtective Coatings

- Materials Selection

- Cathodic Protection

- Corrosion Engineering

- Personnel Training, and

- Best practices in environmental protection to prevent environmental degradation and uphold public health.”

If you’re asking yourself why we must require common sense regulation, you don’t need to look further than the Fern Hollow Bridge in Pennsylvania on January 28, 2022. The bridge had been inspected as recently as October 2021. Yet, despite a 106-page report complete with color photos and a detailed listing of corrosion and decay, the bridge was allowed to remain operational.

Image Extracted From Post-Gazette

The corrosion was especially aggressive because the “chloride-laden liquid from melted snow in winter – would seep through the deck onto the steel superstructure underneath, including the four support legs.”

The 2021 report notes, “The frame legs are in poor condition. The frame legs exhibit laminar rust and holes in the webs. There are five (5) stiffeners at each bent leg that exhibit 100% section loss.” This bridge collapse in Pennsylvania should be a proverbial distress call to everyone with oversight for bridge safety.

What Does Bridge Data Tell Us?

According to the American Road and Transportation Builders Association:

- Every day in the United States, 167.5 million daily bridge crossings occur on 43,578 structurally deficient bridges rated as “in poor condition.”

- If we took the U.S. bridges needing repair and stretched them end-to-end, the repair line would exceed 6,100 miles.

- The U.S. Department of Transportation estimates the cost to replace all these deficient bridges to be $58 billion.

All the reasons above require support for this proposed legislation. We should all demand that any future bridge construction or repair project include surface preparation, protective coating systems, corrosion engineering, and reduced environmental impact. But, if we know we should stop bridge corrosion, what’s the science behind preventing bridge corrosion?

The Science of Bridge Corrosion

EonCoat becomes the obvious answer to corrosion control on carbon steel bridges when you understand the science of corrosion. When speaking with Tony Collins, our CEO, about the grain boundaries mentioned in the article about the Fern Hollow Bridge collapse, he stated,

“Corrosion happens along grain boundaries when they are under tensile stress. The stress pulls the steel apart and makes a tiny gap that enables chloride ions to follow that gap. The chloride ions create corrosion because they pull electrons away from the steel. Lost electrons are always why steel corrodes because the iron atom must bond with something to satisfy the charge imbalance.”

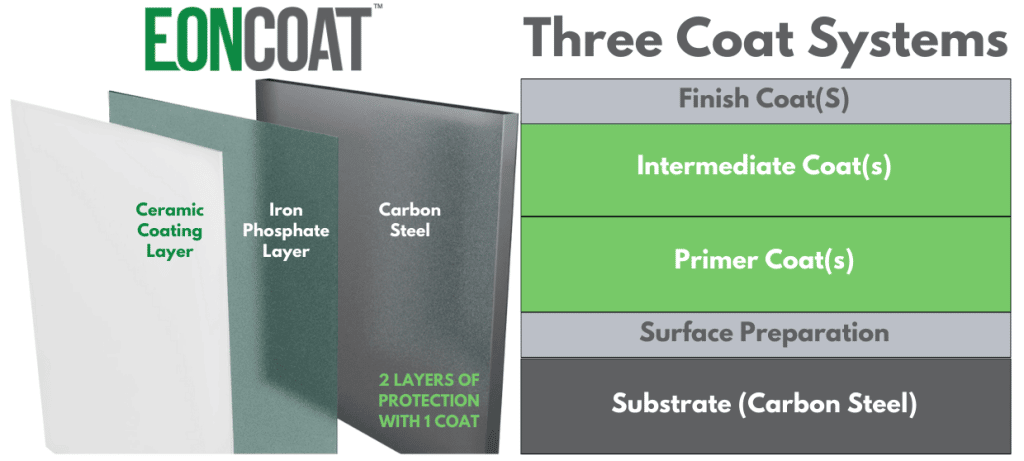

EonCoat has a reservoir of phosphate ions and a chemically bonded phosphate ceramic. As a result, a chemical reaction occurs and EonCoat can follow the chloride ions into the boundaries and stop the corrosion.

Now that you understand the science of EonCoat, let’s look at its Application and Environmental benefits.

Application of EonCoat

If you want to compare EonCoat to a three-coat protective paint system, the benefits of EonCoat quickly come into focus. Corrosion protection can’t simply be painting a bridge. The paint-on-top-of-paint job is never-ending, and you must pay someone to do that. While this may make the bridge look attractive to the untrained eye, the corrosion will still be there, creeping under the paint.

EonCoat is spray applied and will succeed in environments with high humidity and high levels of salt – common conditions near bridges. There is no need to hold the blast or measure for salt content. As the project manager, you can allow flash rust to bloom and keep moving toward your completion date. Tightly bonded flash rust is indicative of a carbon steel substrate surface that will bond well with EonCoat.

With EonCoat, you utilize a Certified EonCoat Applicator and apply the protective coating once. Then, for the next 30 years, you only need to monitor the bridge for corrosion. That will be a tiresome job – there will be no corrosion. Congratulations – you just saved bridge project dollars by applying the permanent corrosion protection coating.

Environmental Benefits of EonCoat

Selecting EonCoat for its environmental benefits while protecting a bridge from corrosion simply makes sense. EonCoat is inorganic and water-based. EonCoat has:

- NO VOCs

- NO HAPs

- NO Toxins

- NO Odor

- NO hazardous material disposal requirement

- Non-flammable

- Reduced PPE Requirement – N95 and goggles are sufficient

When you protect a bridge with EonCoat, you’ll save bridge project money on environmental costs.

If you’d like to learn more about EonCoat, sign up for our Free E-Book (your email address is always safe with us). In the alternative, feel free to click the “Contact Us” button below and tell us how we can help you solve corrosion.

Ready to Learn More About EonCoat?