What is a pipeline?

Pipelines are precisely what their name implies. Mission-critical, carbon steel pipelines can be above ground or buried several feet underground. The pipe may sweat, leading to a more rapid rate of pipe corrosion, or the pipe may require insulation. Pipeline systems fall into one of three categories – transportation, gathering, or distributing.

Today we’re going to focus on the external parts and pipelines made of carbon steel, how corrosion impacts those carbon steel pipelines, and how to protect pipelines from corrosion and keep the pipelines – and the people they serve – safe.

How much pipeline is there?

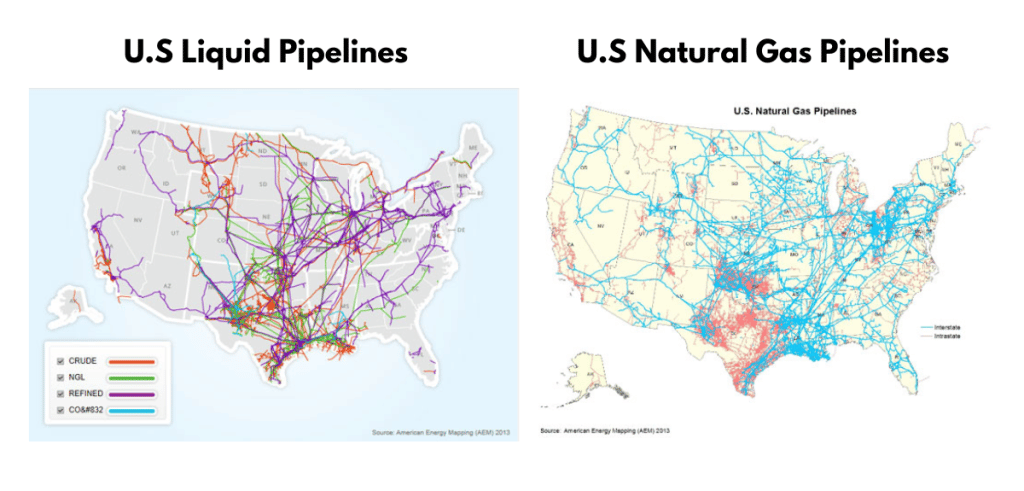

Globally, there are 2.175 million miles of pipeline in 120 nations. The United States has 65% of those miles. The following two closest countries are Russia with 8% and Canada with 3%.

In the United States, a vast array of Federal and State agencies oversee pipelines and their safety. An example of the advantage of such oversight is the transparency in identifying what pipelines are in a geographic region and seeing what they are transporting.

Image extracted from American Petroleum Institute

What do pipelines carry?

Pipelines deliver a wide variety of materials, including:

- water

- various other fluids (beer, anyone?)

- crude oil

- refined petroleum

- sewage

- slurry

- liquid natural gas

- ammonia

- alcohol fuels

- coal and ore after being mixed with water

What is pipeline corrosion?

For this article, we will focus on the externals of a pipe. External corrosion announces itself when the typical three-layer paint protective coating systems fail. The easy failure of paint systems allows the environmental conditions (air, moisture, and salts) to begin their negative impact on the carbon steel pipe materials.

Research is abundant about the various types of carbon steel corrosion. However, according to Tony Collins, our CEO, the answer is simple, “reducing the problem to its simplest form often causes the answer to fall out … Corrosion is about the chemical imbalance created when a carbon steel atom loses an electron and bonds with oxygen to restore the charge imbalance.”

So, whether it’s stress corrosion, galvanic corrosion, or pitting corrosion, it can all be answered with the same corrosion protection method – EonCoat Corrosion Protection.

How to Prevent External Pipeline Corrosion?

The answer to pipeline corrosion protection is to prevent it before corrosion occurs. The current three-coat paint protection systems mechanically lay on the metal surfaces. As a result, the paint does nothing to indicate coating system failure until it’s too late. When an organically occurring scribe or scratch happens, the ambient air, moisture, and salt meet the carbon steel surface and begin the corrosive process.

For a sweating pipeline, the corrosion challenge becomes immediately apparent. The pipeline sweat is created because of the difference in the internal temperature and the ambient temperature. The condensation arrives on the external surface and runs down the sides of the round pipe. The very bottom of a pipeline suffers the highest corrosion rate because of the physics of water movement.

EonCoat Corrosion Protection is successful for both regular and sweating pipelines. Customers frequently ask us about the definition of sweating – a great question. The sweating cannot be a constant drip, but EonCoat can easily tackle mere moisture or damp condensation. EonCoat can be applied directly to the sweating pipeline while it is still in service, eliminating asset downtime.

What about a pipeline that requires insulation?

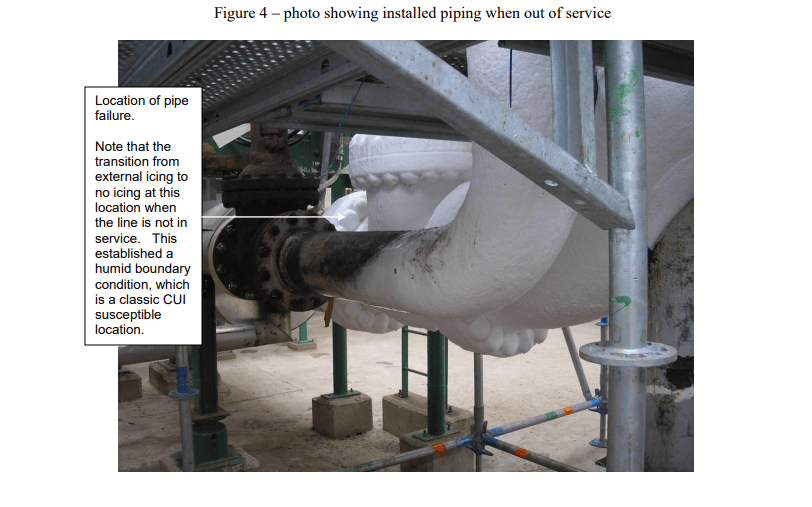

Some pipelines require insulation because of their temperature. The insulation is necessary to prevent heat transfer and to maintain the pipe at a consistent (and safe) temperature. In addition, a CUI protective coating is essential because if the insulation becomes wet – and it will – the moisture and air maintained in pockets of insulation will create corrosion. EonCoat CUI Coating (Corrosion Under Insulation) is the ideal solution for this unique need and is temperature-rated up to 450° C (842° F) and as low as -160° C (-256°F).

Dow Chemical has shared the lessons they learned (sharing lessons learned is a pipeline industry standard) when an 8-inch carbon steel pipe failed. You can see the icing boundary in the picture below. There should have been insulation and a layer of CUI between the pipe and the insulation.

Image extracted from Wermac.org

What about the welds on a pipeline?

If you need to weld on a pipeline after it has been protected by EonCoat, the process is straightforward. You simply remove the coating where the weld will be done, weld, and then use the EonCoat Dual Component Cartridge Spray Gun to touch up the welds. No extra prep work is required.

Video extracted from Liquid Energy Pipelines

The future of pipelines

Whether for the oil and gas industry, water for a municipality, or various other fluids, pipelines are one of the safest ways to transport a significant number of raw and finished materials.

More and more people are talking about the individual, corporate, and global reduction of greenhouse gases (GHG) – those gases that trap heat into the Earth’s atmosphere. It’s nice to know that pipelines are powered primarily by electric pumps with no GHG emissions. No GHG also means that neither the pipeline nor the pump station emits air pollution. When you couple no GHG with the environmentally safe approach of EonCoat, the future looks bright.

If you’d like to tell us about the corrosion problem you’re trying to solve, feel free to click the Contact Us button below. If you’d like to learn more about EonCoat, we invite you to sign up for our Free E-Book.

Come back next week when we talk about the internal corrosion of pipelines.

I’m still trying to get the exact location of the pipeline with the beer – stay tuned for those updates.

Ready to Learn More About EonCoat?