On-Time And On-Budget!

Where Do We Start?

We spend a great deal of time testing the products we will use on the critical equipment in our plants before starting a project. But unfortunately, a disproportionate number of those projects either do not proceed in a timely manner, or the coating fails prematurely, or both.

Why? We select products that will do the job. Our internal and third-party testing proves that the coating we selected will work. So why do we fail so often? The root cause of failure is an application error in more than 90% of the cases. If this is true, how do we do better?

How Do We Evaluate?

Let’s examine the transition from the lab or factory to the field. When we manage factories, we talk about Six Sigma. Six Sigma means that we seek an error rate of less than 6 in 1,000,000 operations. We routinely demonstrate that this is an achievable goal – both in the research lab and the factory. This goal is hard to reach in the field because we are dealing with humans. I would argue that this is a convenient excuse for the root issue. When we apply the lessons of the lab and factory in the field, we lack the systems and processes that deliver the consistent results we see in the more controlled environment of a factory.

So what’s going differently in the field? For as long as we’ve been doing fieldwork, there has been one consistent theory of productivity. Essentially, if everyone on the job site is working, the foreman must be doing his job. Every foreman has used the phrase – “I’ve got everybody busy.” While that phrase may sound tremendous or even be pleasing to the eye, nothing could be more wrong. The goal should never be keeping people busy. The goal should always be moving the job towards completion.

Like this:

How Do We Know If We Are Moving In The Right Direction?

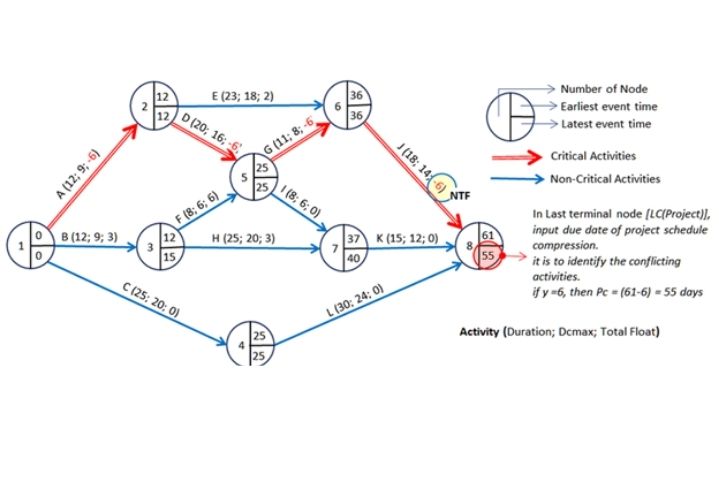

There is only one way to know if you are working productively towards the project’s conclusion. You must have a plan that tells you what tasks are relevant to a job’s movement toward its conclusion. This plan is called the Critical Path on a type of project plan called a CPM Network Diagram. That hyperlink for the CPM Diagram contains a perfect example – fabricating a tank – except they need to add the step labeled “Apply EonCoat.”

It is not easy, perhaps not possible, to intuitively know the most direct path between the beginning and end of the work. So, we map it out in a Network Diagram. Once we map out the necessary order of the tasks and determine how long each task will take, it is easy to see the quickest way to get to the end of the job. My Dad, Vernon, used to say, “Planning is like motherhood; everyone is in favor of it, but very few want to do the hard work involved.”

Trying to skip the hard work of laying out such a plan is like driving across the country without laying out the route on a map. You may reach the destination, but you will not do so as soon as you could have. Likewise, laying out a well-mapped plan is hard work. All tasks not on the Critical Path only take labor. But those tasks on the Critical Path must carry the overhead because they determine the length of the job. As a result, great project managers always have as many people as required working the Critical Path at all hours.

What Do Checklists Accomplish?

Tasks represent the plan. Every task on the plan should have a checklist of how to do it. In addition, every checklist should have a signoff box by the person who does it and the person responsible for the outcome.

The checklist of task completion should be part of a daily report submitted by the contractor to the owner. This checklist/signoff sheet is a powerful tool if properly employed. The contractor must be the owner and producer of the checklist. He must get the inspector to sign off when he satisfactorily completes a task. Tasks can have monetary values for progress payments. Until a signoff sheet for the task is complete and the task is marked off the CPM Network Diagram, it should not be approved for payment.

The CPM Network Diagram and corresponding checklists are tools that deliver immense power to the inspector to act in the customer’s interest. If the inspector doesn’t sign off on a process, the contractor knows he will not get paid. This situation forces the contractor to discuss a task with the inspector before doing the work. Ideally, the contractor and inspector agree on the process, expectations, and performance at the task is even started. The unique system forces the inspector and contractor to work together in the customer’s interest. If there is a disagreement between the contractor and inspector, they should take it to the customer. The discussion with the customer should occur before both time and money are wasted.

This built-in, seemingly-forced collaboration saves money and time for the contractor and the customer. Things get done once – correctly.

It is essential that the inspector report directly to and be paid by the customer. Sometimes it seems simpler to have the contractor pay for the technical support. However, this puts the inspector in a poor position. Many a contractor foreperson has said to an inspector – “you work for me,” and “I’ll make the decisions; you are just here in case I have a question.” This framework is never appropriate and should not be tolerated.

What’s A Daily Report And Why Does It Matter?

Another critical component for running a job well and staying on the Critical Path is the daily report. The daily report must be submitted by the contractor each day, and at a minimum, it should have four things:

1- Tasks completed – right from the CPM

2- Any unusual or unexpected conditions encountered

3- Contractor recommendations, if any

4- What the contractor needs the customer to do if anything.

The best contractors will also submit a cost report daily. The cost report should show exactly where the job is financially each day. Too many jobs start with a budget of X and wind up with a cost of 2X. This scenario causes everyone to become angry. Contractors must make concessions for any activities they cannot prove. The customer gets in hot water with his management because he is over budget. All the surprise budget and time issues are needless.

If the money is monitored daily and discussed in the customer’s daily meetings, you can address cost increases before they get out of hand. Managers can make sound data-based decisions and select their next best step if they have the correct information. Running a tight ship with daily accountability will sound impossible to some readers. However, this author ran a high-eight-figures contracting business, and every customer got a detailed cost report, to the penny, every day before 11 AM that was current as of 7 AM. This daily reporting eliminated the frustration that comes with unexpected bills after the fact. None of us like unexpected costs.

What Are The Two Necessary Components To Success?

If you’ve read this far, you have probably realized that getting stellar results comes down to 2 primary things –

1- Planning

2- Communication

Typically, we do neither on many application jobs. Owners do not communicate to the contractor what they expect. Contractors do not communicate with customers what they can expect, what they are doing, and how much money they are spending. Contractors and Inspectors do not communicate with each other to plan the optimal activities that are the essence of the Critical Path. Perhaps worst of all, no one communicates to the crew exactly what they are supposed to do. It is endemic that applicators and painters do not know what a customer, contractor, or inspector expects from them. We tend to blame them for the shortcomings of poor application results. Perhaps we do this because it is too painful to look in the mirror and see the real culprit.

How Have We Decided To Be Different?

At EonCoat, we focus on three things in our continuous quality improvement process to make every application job successful:

1. Does the customer know what they are buying and what to expect, and how can we make this clear?

2. Does the contractor know how to manage the project in terms of environment, surface preparation needs, and application timeframe?

3. Does the applicator know how to use and maintain the equipment and apply the product?

We work diligently to make it easier for contractors to see where our product fits into their Critical Path. If you visit our office, you will frequently hear the question, “What’s the next best step?” For example, we recently published an updated Application Guide webpage that has its own downloadable and printable checklist. We have done the same thing for Surface Preparation which has its own checklist. In addition, when we meet with customers or contractors, we talk specifically about the inspector and applicator roles while EonCoat is being applied.

EonCoat’s goal has always been and continues to be the Sigma standard, or damn close to it.

Ready to Learn More About EonCoat?